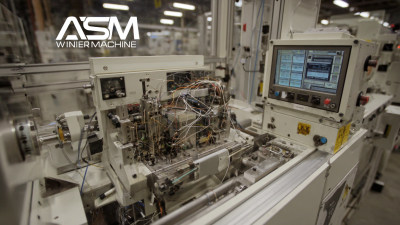

In the rapidly evolving landscape of electronics manufacturing, the significance of Gold Wire Bonding has become increasingly prominent. This technique, traditionally employed to establish electrical connections between semiconductor chips and their packages, is witnessing innovative applications that enhance performance, reliability, and efficiency. As manufacturers strive to meet the growing demands for smaller, faster, and more sophisticated electronic devices, Gold Wire Bonding presents a compelling solution.

This blog will delve into a comparison of various innovative uses of Gold Wire Bonding, exploring its benefits and challenges across different applications in the electronics industry. By examining case studies and emerging trends, we aim to shed light on how this critical technology shapes the future of electronics manufacturing.

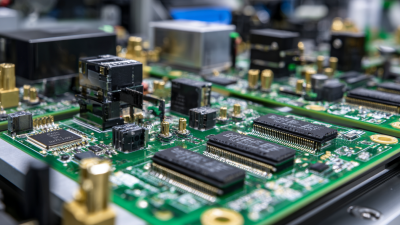

Emerging trends in gold wire bonding technology are reshaping the landscape of electronics manufacturing, driven by the increasing demand for advanced and efficient interconnect solutions. As the semiconductor industry faces the challenge of rising gold prices, manufacturers are exploring innovative alternatives such as aluminum-clad copper thick bonding wires. These new materials not only offer cost benefits but also enhance electrical and thermal performance, making them ideal for advanced applications in power electronics and electric vehicles.

Emerging trends in gold wire bonding technology are reshaping the landscape of electronics manufacturing, driven by the increasing demand for advanced and efficient interconnect solutions. As the semiconductor industry faces the challenge of rising gold prices, manufacturers are exploring innovative alternatives such as aluminum-clad copper thick bonding wires. These new materials not only offer cost benefits but also enhance electrical and thermal performance, making them ideal for advanced applications in power electronics and electric vehicles.

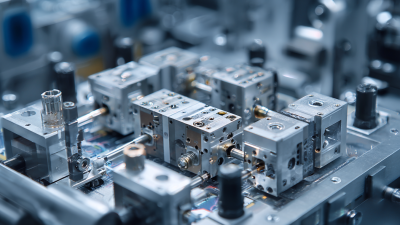

Additionally, the global wire bonder equipment market is anticipated to grow significantly, fueled by the rising global electronics production. This surge is backed by advancements in MEMS technologies, particularly in inductor fabrication, which are opening new avenues in neurotechnologies and power applications. The integration of AI in market analyses points to a transformative era for wire bonding processes, where automation and precision can improve efficiency and reliability. As these trends continue to evolve, gold wire bonding will remain a vital component, adapting to the industry's demands while maintaining its reputation as the gold standard in semiconductor packaging.

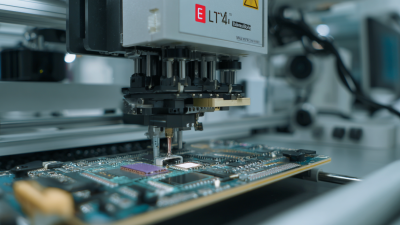

Gold wire bonding is emerging as a critical component in enhancing performance metrics within the electronics manufacturing industry. This technique offers superior electrical conductivity and thermal reliability compared to traditional bonding methods. According to industry reports, gold wire bonding can reduce loop height variations, a significant factor in ensuring the reliability of interconnections in semiconductor devices. Research indicates that the loop height of gold wire can achieve optimal configurations, thus enabling increased density and performance in advanced packaging applications.

Furthermore, the reliability of gold wire bonding is demonstrated in various metrics, such as failure rates and thermal cycling performance. A notable study highlighted that devices utilizing gold wire show a failure rate reduction of approximately 30% in comparison to those using copper wire bonding. This improvement is crucial in meeting the growing demands for higher performance and durability in automotive and consumer electronics. As manufacturers strive to innovate, the adoption of advanced gold wire bonding techniques is poised to drive significant improvements in product reliability and performance across the electronics sector.

When considering cost-effectiveness in electronics manufacturing, gold wire bonding stands out as a smart investment. Its high conductivity and resistance to oxidation contribute not only to the reliability of electronic components but also to long-term savings. A recent industry report indicates that gold wire bonding can reduce the total lifecycle cost of devices by up to 20% due to minimized failure rates and enhanced performance. This fact may resonate particularly well with manufacturers aiming to maximize efficiency without sacrificing quality.

**Tips:** Opt for competitive pricing when sourcing materials for gold wire bonding. Searching for suppliers that offer bulk discounts can lead to significant savings. Additionally, leverage technological advancements; automated processes in wire bonding have been shown to improve throughput and reduce labor costs while maintaining high precision.

As silver and copper bonding alternatives gain popularity, gold wire bonding remains superior in many applications, especially in high-frequency devices. The longevity and reliability of gold wire bonds are substantial, often leading to lower warranty claims and maintenance costs. Thus, while initial costs may be higher, the overall financial benefits support gold's place as a preferred material in high-end electronics.

**Tips:** Keep informed about any emerging advancements in gold bonding technology that could offer improved efficacy or cost advantages, and consider continuous training for your workforce to keep pace with industry standards and techniques.

| Application | Benefits | Cost Comparison (% Savings) | Durability |

|---|---|---|---|

| Consumer Electronics | High conductivity and reliability | 15% | Excellent |

| Automotive Electronics | Resistant to corrosion and high temperatures | 10% | Very Good |

| Medical Devices | Biocompatibility and low thermal expansion | 20% | Excellent |

| Telecommunications | Enhanced signal integrity | 12% | Good |

| Aerospace | Reliable performance in extreme conditions | 18% | Excellent |

The incorporation of gold wire bonding in electronics manufacturing not only enhances device performance but also aligns with environmentally friendly practices. Gold, renowned for its exceptional conductivity and resistance to oxidation, allows for the creation of highly reliable electronic components. As manufacturers continue to shift towards sustainability, gold wire bonding presents an attractive option due to its longevity and recyclability. Unlike other materials that may degrade or emit harmful substances, gold maintains its integrity over time, reducing electronic waste and promoting a greener manufacturing process.

Recent developments highlight the growing importance of eco-conscious manufacturing choices, particularly in regions like California where environmental regulations are evolving. The push for sustainable practices is crucial, especially amid legislative changes that may relax standards for industrial projects. By integrating environmentally friendly methods like gold wire bonding, electronics manufacturers can demonstrate their commitment to sustainability while still meeting innovation demands. This dual focus on performance and environmental responsibility not only benefits the planet but also enhances brand reputation in an increasingly eco-aware market.

As technology continues to advance, the future of gold wire bonding in electronics manufacturing is ripe with possibilities. Innovations in materials science and engineering techniques are leading to new applications that can enhance the efficiency and reliability of electronic components. For instance, the development of thermocompression bonding techniques offers improved interconnect reliability, which is crucial in high-performance environments such as automotive and aerospace sectors. This evolution ensures that gold wire bonding not only maintains its relevance but also becomes an indispensable part of next-generation electronic devices.

Moreover, the integration of gold wire bonding with cutting-edge assembly processes, such as ultra-thin packaging and 3D integration, signals a significant shift in manufacturing paradigms. This fusion opens new avenues for miniaturization without compromising performance, addressing the industry's growing demand for smaller, more efficient devices. As we explore these future innovations, it is clear that gold wire bonding will continue to play a pivotal role in driving advancements in electronics manufacturing, ultimately shaping the devices of tomorrow and enhancing their functionality in our increasingly digital world.