In the rapidly evolving landscape of electronics, the importance of die bond technology cannot be overstated, as it serves as a fundamental process in semiconductor manufacturing that significantly influences overall performance. According to a report by Gartner, the global semiconductor industry is projected to reach $1 trillion by 2030, highlighting the critical demand for advanced manufacturing techniques. Die bond, which involves the attachment of semiconductor chips to their substrates, is pivotal in ensuring thermal management, electrical conductivity, and package integrity. With emerging applications in 5G communications and artificial intelligence, optimizing die bond processes will be essential for meeting the performance expectations of next-generation electronic devices. As power densities increase and device miniaturization becomes more prevalent, innovative die bond methods will play a crucial role in enhancing semiconductor reliability and performance, paving the way for future technological advancements.

Die bonding is a pivotal process in semiconductor manufacturing, playing a crucial role in determining the reliability and longevity of electronic components. According to a recent report by Yole Développement,

die bonding techniques directly impact the thermal and mechanical performance of semiconductors, which are essential for the operation of devices in challenging environments. The report highlights that up to 30% of failures in electronic devices can be traced back to issues related to die attach quality, underscoring the importance of optimizing this phase to ensure high durability.

Die bonding is a pivotal process in semiconductor manufacturing, playing a crucial role in determining the reliability and longevity of electronic components. According to a recent report by Yole Développement,

die bonding techniques directly impact the thermal and mechanical performance of semiconductors, which are essential for the operation of devices in challenging environments. The report highlights that up to 30% of failures in electronic devices can be traced back to issues related to die attach quality, underscoring the importance of optimizing this phase to ensure high durability.

In terms of longevity, the advancements in die bonding materials, such as the adoption of silver sintering and advanced epoxy adhesives, have shown a significant improvement in reliability. Research by TechInsights reveals that these modern materials can enhance bond strength by as much as 50% compared to traditional methods, which is critical for applications requiring high thermal conductivity and resistance to thermal cycling. As the industry continues to push for smaller, more efficient chips, the role of die bonding in alleviating stress and preventing premature failure will only grow, making it an essential area of focus for semiconductor manufacturers aiming to enhance product life span and reliability.

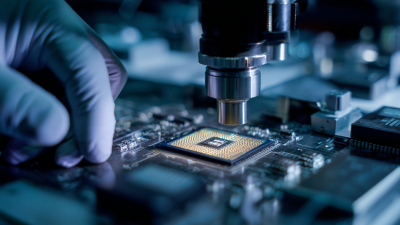

Die bonding is a crucial step in semiconductor manufacturing that directly impacts the performance and reliability of electronic devices. Among the various techniques employed in the industry, adhesive bonding, eutectic bonding, and thermocompression bonding stand out for their unique advantages and application suitability. Adhesive bonding utilizes polymer-based materials, offering a cost-effective solution for less demanding applications, while providing excellent thermal and electrical insulation. This method is widely used in consumer electronics where performance requirements are moderate.

On the other hand, eutectic bonding is favored for its superior thermal and mechanical properties, making it ideal for high-performance applications like power electronics and high-frequency devices. This technique involves the melting of alloy materials, creating a strong bond conducive to efficient heat dissipation. Thermocompression bonding, characterized by its ability to achieve fine pitch interconnections, is increasingly important in advanced packaging techniques, including 3D chip stacking. By evaluating these bonding techniques and their respective industry standards, manufacturers can make informed decisions that ultimately enhance semiconductor performance and meet the evolving demands of modern electronics.

Die bonding is a pivotal process in semiconductor manufacturing that significantly impacts the thermal management of electronic devices. Effective thermal management is essential to ensure that semiconductor components operate within safe temperature parameters. Poor thermal management can lead to overheating, which not only reduces performance but can also compromise the longevity of the device. The choice of die attach materials, the bonding techniques employed, and the overall design of the thermal interface all play crucial roles in how heat is dissipated from the semiconductor die.

Furthermore, advancements in die bonding technology have led to enhanced thermal conductivities and improved heat spreading capabilities. Techniques such as eutectic bonding and using advanced materials like silver-filled epoxy enable more efficient heat transfer away from the die, promoting better device performance. As semiconductors continue to shrink in size while increasing in power density, addressing thermal management through optimized die bonding will be vital for the development of next-generation electronics. This not only maximizes operational efficiency but also propels the innovation of more compact and powerful electronic devices.

Die bonding plays a pivotal role in the performance of semiconductors, particularly as the industry shifts towards advanced packaging techniques like 2.5D and 3D integration. The emergence of hybrid bonding technologies has transformed the landscape, facilitating the vertical stacking of chips without sacrificing signal integrity. This process, which combines metal bonding with non-conductive adhesives, addresses the rising demand for higher interconnect density and lower power consumption, as elucidated by recent reports from industry analysts suggesting that the advanced packaging market continues to expand despite economic fluctuations.

Key materials utilized in die bonding include advanced adhesives and thermal interface materials that ensure efficient heat dissipation and reliability over time. With rising expectations for multi-chip components that incorporate materials with distinct physical properties, the challenges associated with manufacturing and packaging escalate. Studies indicate that maintaining yield rates and onsite reliability in these configurations is paramount, as poor bonding can compromise device performance. As the semiconductor industry evolves, the exploration of newer materials and technologies in die bonding remains critical for the future development of high-performance electronics.

In recent years, die bonding technology has become increasingly pivotal in enhancing semiconductor performance for next-generation electronic applications. Reports from the Semiconductor Industry Association (SIA) indicate that the global semiconductor market is expected to reach $1 trillion by 2030, with innovations in die bonding contributing significantly to this growth. Advanced materials and techniques, such as silver sintering and polymer-based adhesives, are being explored to improve thermal conductivity and mechanical stability, essential for high-performance electronics.

As devices continue to shrink in size and increase in complexity, the need for reliable die bonding processes is more critical than ever. A study by MarketsandMarkets forecasts that the die bonding equipment market will expand at a CAGR of 7.1%, reaching approximately $2.5 billion by 2026. Innovative solutions, such as laser-based bonding techniques and automated die bonding systems, are enhancing production efficiency and precision, addressing the rising demand for compact and efficient electronic systems across industries, including automotive and consumer electronics.

| Technology | Die Bonding Method | Material | Performance Metric | Future Trend |

|---|---|---|---|---|

| Power Electronics | Eutectic Bonding | Gold | Thermal Conductivity | Increased Efficiency |

| RF Devices | Hybrid Bonding | Aluminum | Signal Integrity | Miniaturization |

| Sensor Technology | Laser Bonding | Copper | Pressure Sensitivity | Smart Applications |

| Automotive Electronics | Flip-Chip Bonding | Silver | Reliability | Automated Systems |