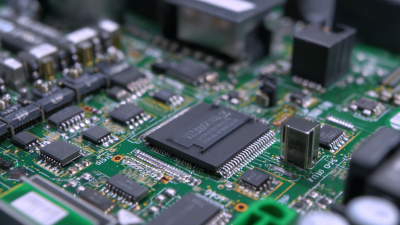

In the realm of semiconductor manufacturing, the efficiency and quality of wire bonding processes are crucial for ensuring optimal performance in electronic devices. One of the key factors that can significantly influence the success of these processes is the selection and implementation of appropriate Wire Guides and Ribbon Guides for Wire Bonders. These components play a vital role in accurately positioning and controlling the wire during bonding, thereby enhancing the precision and reliability of connections. By understanding the various types of wire and ribbon guides available, as well as the best practices for their use, engineers and manufacturers can streamline their wire bonding processes, reduce defects, and ultimately increase yield. This guide aims to provide insights into how to optimize wire bonding operations through the strategic selection and application of wire and ribbon guides, paving the way for improved product quality and production efficiency.

Wire and ribbon guides play a critical role in the wire bonding process, acting as essential components that ensure accuracy and quality in the connection of semiconductor devices. The effectiveness of these guides can greatly influence bond strength and reliability. According to a report from the Semiconductor Industry Association (SIA), an estimated 12% of defects in wire bonding are attributed to poor alignment and positioning, which can be mitigated by the proper use of guides. By ensuring precise wire placement, manufacturers can enhance production yields and reduce costly rework.

The importance of wire and ribbon guides is further underscored by industry standards, which highlight their contribution to achieving optimal loop shapes and minimizing wire sweep, a common issue in wire bonding that can lead to faults. A study published in the Journal of Electrical Engineering noted that the implementation of high-quality guides could improve overall bonding consistency by approximately 30%. With advances in material technology, using guides made from innovative materials can also enhance thermal and mechanical stability, further improving the bonding process. Recognizing the importance of these components can lead to significant improvements in the efficiency and reliability of semiconductor manufacturing.

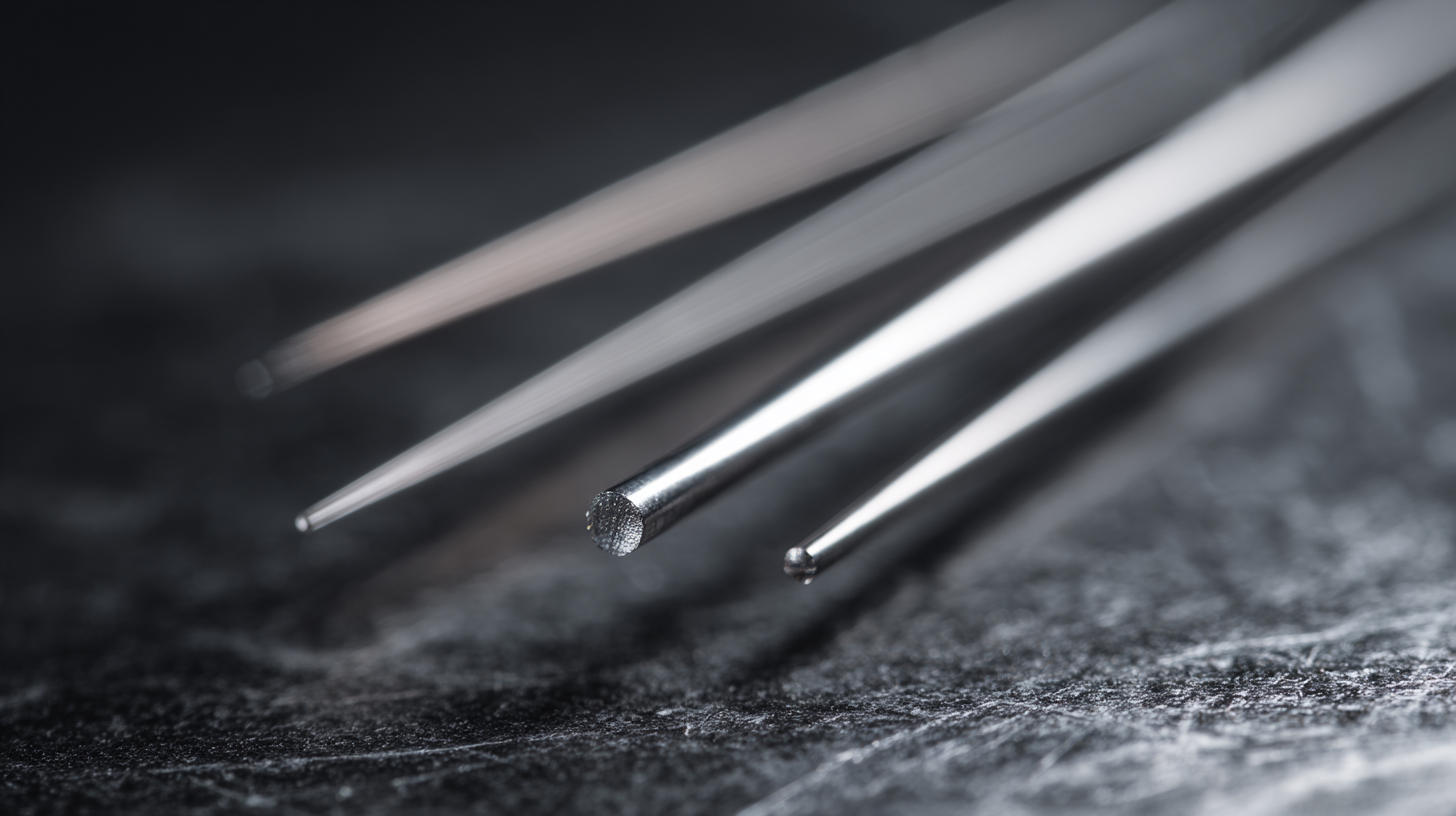

When it comes to optimizing your wire bonding process, selecting the appropriate materials for wire and ribbon guides is paramount to achieving outstanding performance. The right materials can enhance the precision of the wire placement, minimize defects, and allow for higher production efficiency. For instance, using advanced polymers or engineered plastics can offer improved wear resistance and lower friction, resulting in smoother wire movement and less potential for breakage or slippage during the bonding process.

In addition to material selection, evaluating the environmental conditions and compatibility with the specific wire types is critical. Just as different adhesives play crucial roles in bonding metals with various substrates, the choice of wire and ribbon guides must also consider factors such as thermal conductivity, adhesion properties, and the mechanical strength required for your specific application. By carefully considering these variables and following best practices, manufacturers can significantly improve the reliability and quality of their wire bonding processes, leading to greater overall efficiency and product durability.

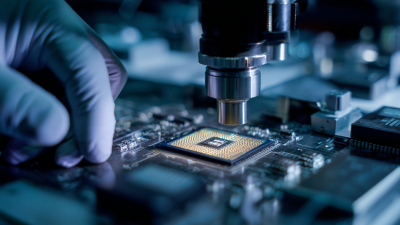

Proper alignment of wire and ribbon guides is crucial for enhancing the wire bonding process. When guides are incorrectly positioned, it can lead to misalignment during bonding, resulting in weak connections and increased failure rates. To optimize the bonding accuracy, technicians should regularly check and adjust guide alignment to ensure that they are perfectly aligned with the bond pads and leads.

In practice, using adjustable guide systems can significantly improve bonding accuracy. These systems allow for fine-tuning of the guide positions, accommodating variations in wire diameters and ribbon widths. Technicians should take extra care to perform alignment checks before each bonding operation, using precision tools such as alignment lasers or optical microscopes. By focusing on the alignment of the guides, manufacturers can reduce the incidence of bonding defects and enhance the overall reliability of their electronic assemblies.

The design of wire and ribbon guides plays a crucial role in enhancing wire bonding efficiency. When evaluating the impact of guide design, it becomes evident that the geometry and material of these guides can significantly influence the quality of bond formation. For instance, a guide that effectively maintains the wire alignment minimizes potential vibrations and deviations during the bonding process, thus reducing the risk of wire breakage or misalignment. Manufacturers must consider various parameters such as guide width, angle, and surface texture to tailor these components for specific bonding applications.

Moreover, the right guide design can improve the thermal performance during the bonding process. A well-engineered guide helps dissipate heat effectively, preventing overheating and ensuring stable bonding temperature conditions. This stability is essential for achieving reliable interconnections and prolonging the lifespan of semiconductor devices.

Additionally, considering the ease of integration and maintenance of guide systems can further streamline the overall wire bonding process, making it not only more efficient but also more cost-effective in the long run. By prioritizing guide design, manufacturers can attain higher yield rates and better performance in their wire bonding operations.

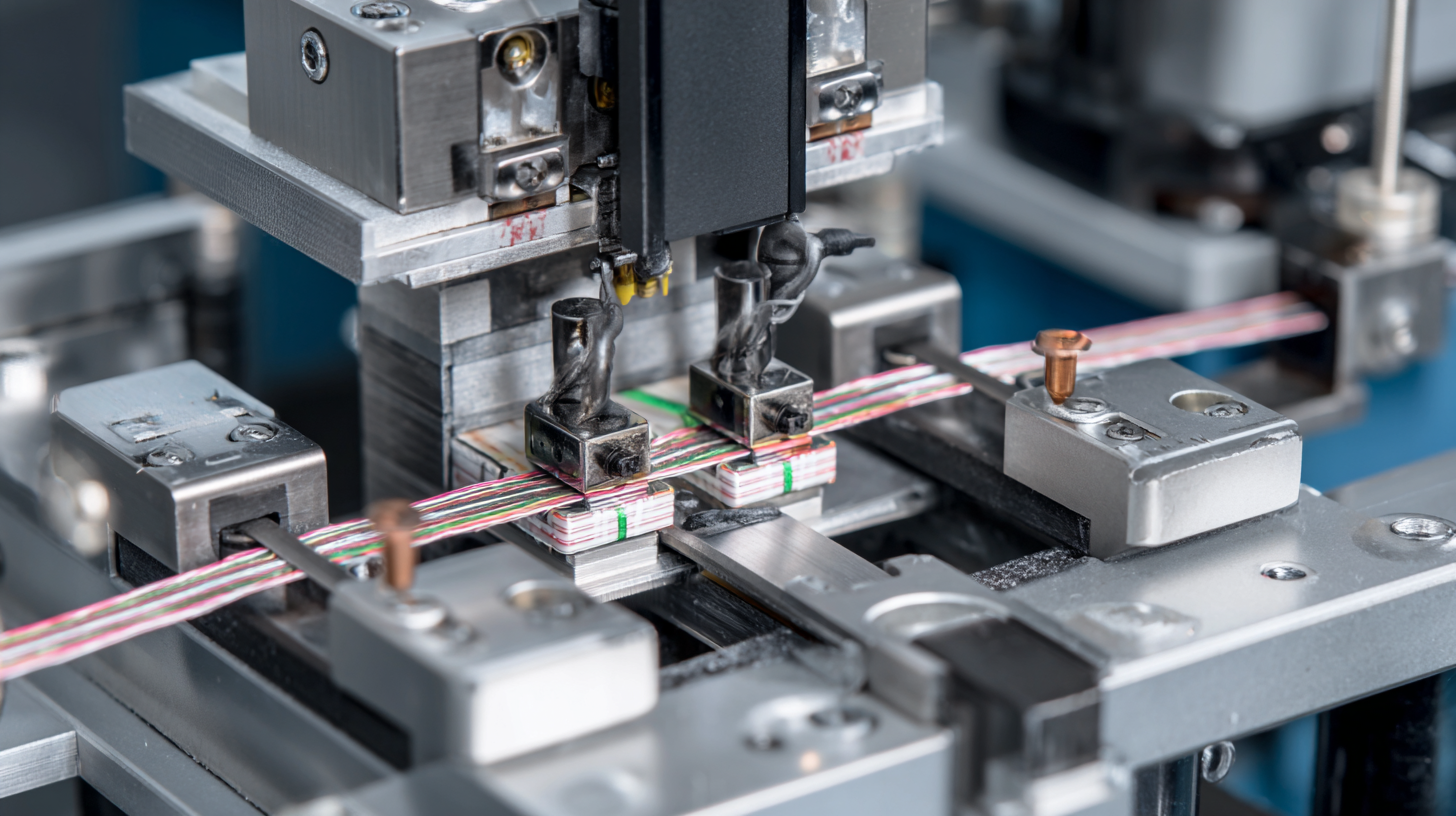

Maintaining and upgrading your wire bonding equipment is crucial for ensuring its longevity and optimal performance. Regular maintenance practices, such as cleaning the bonding tools, checking alignment, and inspecting wire and ribbon guides for wear and tear, can prevent costly downtimes. Establishing a maintenance schedule not only prolongs the life of your equipment but also enhances the overall efficiency of your wire bonding process.

In addition to routine maintenance, considering upgrades can significantly improve the performance of your wire bonding equipment. Incorporating advanced technologies, such as automated alignment systems and high-precision bonding heads, can enhance accuracy and reduce defects. Moreover, selecting the right wire and ribbon guides tailored to your specific applications can streamline operations and minimize material waste. Investing in these upgrades ensures that your equipment remains competitive and capable of meeting the increasing demands of modern manufacturing.

This chart illustrates the improvement in defect rates and efficiency as a result of maintaining and upgrading wire bonding equipment. It highlights the significance of regular maintenance in enhancing production quality and output.