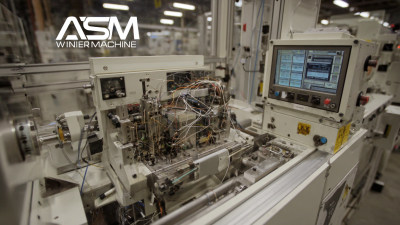

K&S Wire Bonder is a critical tool in the semiconductor industry. Its performance directly impacts the quality of electronic devices. Understanding best practices can enhance its capabilities.

Operators must ensure proper setup and maintenance of the K&S Wire Bonder. Regular inspections can prevent common issues. However, even with thorough checks, some problems may still arise. Each operator’s experience with the equipment can vary, leading to oversight.

Training is vital for optimal performance. Knowledge gaps can result in inefficient operations. Keeping up with the latest tips and techniques can lead to significant improvements. However, there’s always room for growth. Reflecting on past experiences can help operators make better decisions. Embracing both successes and failures is key to mastering the K&S Wire Bonder.

When considering the performance of wire bonders, several key features stand out. Accuracy is paramount. Studies show that a precision of ±1 micron significantly improves the integrity of connections. Adjustable parameters allow operators to adapt to different materials, enhancing efficiency.

Another vital aspect is the control of temperature and pressure. Excessive heat can damage sensitive components. On the flip side, insufficient pressure may lead to weak bonds. Finding the right balance is critical. Reports indicate that an appropriate heat range of 150°C to 200°C can yield optimal results without compromising the component’s integrity.

Tips: Regular maintenance of your bonder can mitigate issues. Check for wear on bonding tools frequently. Operators should also engage in training sessions to understand best practices. This awareness can prevent costly mistakes and improve overall performance.

Efficiency can sometimes be a double-edged sword. Pushing for speed may sacrifice quality. Monitoring cycle times is essential, as neglecting this can lead to inconsistent outcomes. Properly calibrated machines and skilled operators can help mitigate risks while ensuring reliable performance.

Proper setup and calibration of wire bonders is crucial for achieving optimal performance. Misalignment, improper pressure, and incorrect temperature can lead to significant issues. Research from various industry reports shows that up to 35% of production defects stem from setup errors. These issues often reduce yield rates, impacting overall profitability.

To ensure an accurate setup, focus on bond pad alignment. Use a microscope to verify alignment visually. The bonding parameters, such as force and time, should match the materials being used. Adjustments based on specific material properties can greatly increase bond strength. However, technicians often overlook routine calibration, leading to variations in performance over time.

Regularly revisiting machine settings can improve consistency. Identify common patterns in defects and adjust processes accordingly. For instance, an increased ambient temperature can affect the bond quality. Additionally, training staff on the importance of precise calibration can lead to better quality control. Implementing a checklist for daily setup can also help in minimizing errors.

Wire bonding is a critical process in semiconductor packaging. However, challenges often arise, affecting overall performance. One common issue is the bond quality. Inspecting bond strength is essential. Weak bonds can lead to failure during operation. Improper parameters like pressure and temperature could cause this. It’s vital to follow recommended guidelines but stay adaptable.

Another frequent challenge is wire breakage during bonding. This can stem from improper handling or equipment settings. Ensuring the wire is free of defects is crucial. Sometimes, the bonding tool’s alignment is off. This misalignment can lead to uneven pressure. Regular calibration of equipment helps mitigate such risks, although it requires time and diligence.

Additionally, environmental factors play a role. Humidity and temperature fluctuations can create inconsistencies. Maintaining a stable environment might seem trivial, yet it is essential. Operators need to remain vigilant. An overlooked condition can result in unwanted surprises later.

Reflection on past failures improves future practices, fostering continuous improvement in wire bonding.

To maintain the longevity of wire bonders, regular upkeep is crucial. Start by cleaning the bonding tool frequently. Debris can accumulate and affect performance. Use appropriate cleaning agents to avoid damage. Ensure that all parts are inspected for wear. Components like capillaries can wear down, leading to inconsistencies.

Monitoring temperature is essential. High heat can cause components to wear out faster. Keep an eye on the operational environment. Excess humidity can also be detrimental. Adjust these conditions to enhance performance and durability. Track usage patterns, noting when issues arise. This helps in anticipating maintenance needs.

Don't ignore software updates. Inadequate software can lead to functionality problems. Stay informed about the latest features. Regularly check settings to optimize performance. Reflect on past maintenance gaps to improve future practices. Each oversight can lead to operational inefficiency. Commit to ongoing training for the team.

This chart shows the recommended maintenance frequency in hours for optimal performance and longevity of K&S wire bonders across different maintenance intervals.

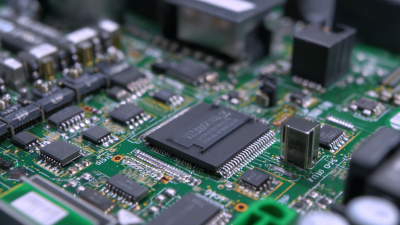

When selecting materials for wire bonding applications, several factors come into play. The choice of wire, substrate, and bonding method can significantly impact performance. Consider the wire material: gold, aluminum, and copper each have unique properties. Gold provides excellent conductivity but can be costly. Aluminum is less expensive but may require careful handling. Copper has a high strength-to-weight ratio, yet it may have oxidation issues. Each material has a balance between performance and cost.

**Tip:** Always evaluate the environment where the bonded components will operate. Temperature and humidity can affect material behavior. For instance, aluminum may perform poorly in humid conditions unless properly coated.

Another critical aspect is substrate compatibility. The thermal expansion coefficients of materials should match closely. Mismatched expansion can lead to mechanical stresses. These stresses may cause bond failures over time. It’s essential to conduct tests to verify the bonding strength and longevity.

**Tip:** Don’t overlook the thickness of the wire. Thicker wires can provide more mechanical support but may require more energy to bond successfully. Experiment with different thicknesses to find the best fit for your specific application.

Reading the assembly guidelines can provide crucial insights into material selection. Understanding the strengths and weaknesses of each material will minimize potential issues and contribute to better overall performance.