The landscape of precision engineering is evolving at an unprecedented pace, driven by the relentless pursuit of efficiency and accuracy. Among the critical components in this field are Die Pick Up Tools and Collets, which are essential for the precise handling of parts during manufacturing processes. According to a report by Gartner, the global precision engineering market is projected to reach $89.5 billion by 2025, highlighting the increasing demand for advanced tools and technologies.

Innovations in Die Pick Up Tools and Collets not only enhance production efficiency but also significantly reduce downtime and material waste. As manufacturers seek smarter, more automated solutions, the integration of advanced materials and digital technologies into these tools will be pivotal in shaping the future of precision engineering.

By exploring the latest advancements and best practices, this blog will guide you through the transformative potential of Die Pick Up Tools and Collets in driving operational excellence.

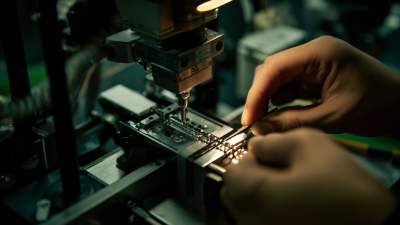

In recent years, innovative die pick up tools have revolutionized precision engineering practices, leading to significant advancements in manufacturing efficiency. According to a report by MarketsandMarkets, the global precision engineering market is projected to grow from $787 billion in 2022 to $1,030 billion by 2027, with a compound annual growth rate (CAGR) of 5.8%. This growth is largely driven by the integration of advanced tooling solutions, which include state-of-the-art die pick up tools designed to minimize waste and enhance processing accuracy.

These tools leverage cutting-edge materials and designs that improve grip and reduce the risk of damage during handling. For instance, the implementation of advanced collet designs with tailored clamping pressure has demonstrated to enhance tool life by up to 30%. Additionally, the real-time monitoring capabilities embedded in these tools not only streamline operations but also provide critical data that informs future engineering decisions—showcasing a strong shift towards data-driven precision engineering. As industries continue to evolve, embracing these innovative die pick up tools could be the key to unlocking unparalleled efficiency and quality in production processes.

| Tool Type | Material | Diameter Range (mm) | Max Load Capacity (kg) | Innovative Feature |

|---|---|---|---|---|

| Die Pick Up Tool | Aluminum Alloy | 5 - 20 | 150 | Anti-Slip Grip |

| Collet | Steel | 2 - 12 | 100 | Self-Centering Design |

| Die Pick Up Tool | Carbon Fiber | 3 - 15 | 200 | Lightweight Construction |

| Collet | Titanium | 5 - 25 | 120 | Heat-Resistant |

The future of precision engineering is significantly shaped by the application of advanced materials, particularly in enhancing the performance of collets used in die pick-up tools. As industries continue to demand greater efficiency and reliability, there is a growing emphasis on incorporating engineered mycelium composite materials. Recent developments indicate that these materials, derived from fungal biorefineries, can effectively replace traditional options like foam and plastic, offering both sustainability and improved mechanical properties.

Research reveals that the use of advanced honeycomb designs in conjunction with these composites can optimize structural integrity while minimizing weight. The mechanical properties of these newly engineered honeycombs are significantly superior, providing enhanced load-bearing capabilities crucial for high-precision applications. According to industry reports, integrating such innovative materials can lead to a potential increase in efficiency by up to 30%, drastically reducing material waste and improving overall production effectiveness.

As companies continue to innovate, the emphasis on advanced materials in the development of collets will not only push the boundaries of precision engineering but also pave the way for a more sustainable future in manufacturing. The intersection of these advancements presents an exciting opportunity to rethink traditional methods and embrace a new era of manufacturing excellence.

The landscape of die handling solutions is rapidly evolving, fueled by smart technologies that are redefining automation and efficiency in precision engineering. Advanced automation systems now leverage artificial intelligence and machine learning to enhance the accuracy and speed of die handling processes. This shift not only increases productivity but also reduces the risk of human error, allowing manufacturers to maintain high standards of quality.

The landscape of die handling solutions is rapidly evolving, fueled by smart technologies that are redefining automation and efficiency in precision engineering. Advanced automation systems now leverage artificial intelligence and machine learning to enhance the accuracy and speed of die handling processes. This shift not only increases productivity but also reduces the risk of human error, allowing manufacturers to maintain high standards of quality.

Tips for implementing smart technologies in die handling include investing in integrated software that can monitor and analyze die performance in real-time. This not only ensures proactive maintenance but also aids in optimizing workflows. Additionally, consider using automated pick and place systems equipped with sensitive sensors that can distinguish between various die types, ensuring more precise handling.

As we move forward, the incorporation of IoT in precision engineering will further streamline die pick-up tools and collets. By connecting machinery directly to analytical platforms, manufacturers can gain valuable insights into performance metrics. This data-driven approach will enable better decision-making, leading to enhanced efficiency in die handling operations.

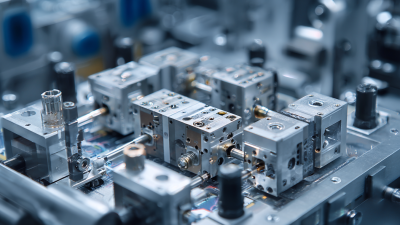

In the ever-evolving landscape of precision engineering, high-precision collets play a pivotal role in enhancing manufacturing efficiency. These tools are designed to provide optimal grip and stability, resulting in superior accuracy during machining processes. Unlike traditional collets, high-precision variants are engineered to accommodate tighter tolerances, which significantly reduces the likelihood of errors and rework. By minimizing fluctuations during operations, manufacturers can achieve a higher quality of finished products and a more streamlined production process.

Moreover, the adoption of high-precision collets can lead to a notable increase in tool life. Their superior grip reduces wear and tear on both the tool and the workpiece, ultimately resulting in fewer replacements and less downtime. With enhanced performance and durability, companies can optimize their operational efficiency, leading to significant cost savings. The integration of these advanced collet systems not only accelerates production timelines but also elevates the overall reliability of manufacturing processes, making them an essential component for businesses aiming for excellence in precision engineering.

This chart illustrates the comparative manufacturing efficiency of high precision collets versus standard collets. High precision collets achieve a notable efficiency of 90%, compared to standard collets at 70%, highlighting the significant advantages of adopting precision engineering tools in manufacturing processes.

As we look ahead at the advancements in precision engineering, die pick up systems are poised for significant transformations. According to a recent report by MarketsandMarkets, the global precision engineering market is expected to grow from $10 billion in 2023 to over $15 billion by 2028, highlighting the increasing demand for innovative tooling solutions. One of the key trends driving this growth is the integration of smart technology into die pick up tools and collets. With the rise of Industry 4.0, manufacturers are adopting smart sensors and automation to enhance production efficiency and reduce downtime.

Tip: To stay ahead in the market, invest in training your workforce on the latest technologies related to die pick up systems. Understanding how to leverage these innovations will improve not only operational efficiency but also product quality.

Moreover, the move towards lightweight yet durable materials is reshaping the design of collets and related tools. Studies have shown that tools made from advanced composites can result in a weight reduction of up to 30%, leading to greater ease of use and enhanced speed in assembly lines. As companies embrace these materials, we can expect improvements in tool longevity and operational performance.

Tip: Evaluate your current die pick up tools' material composition and consider upgrades to advanced composites to reap the benefits of reduced weight and increased durability in your production processes.