In the ever-evolving landscape of manufacturing and DIY projects, selecting the right Epoxy Stamping Tool has become crucial for businesses striving for both quality and efficiency. According to a recent industry report by Grand View Research, the global epoxy market is projected to reach USD 11.74 billion by 2025, highlighting the growing demand for reliable tools that can leverage the advantages of epoxy materials. With increasing applications in automotive, construction, and electronics, the need for robust stamping tools that provide precision and durability is more pronounced than ever. This comprehensive guide aims to equip business owners with essential insights into choosing the best Epoxy Stamping Tool that meets their specific needs, ensuring optimal performance and customer satisfaction.

When exploring epoxy stamping tools, it's essential to understand the various types available and their specific applications in your business. Epoxy stamping tools can be broadly categorized into manual, pneumatic, and electric options, each designed to cater to different operational needs. According to a recent industry report by Grand View Research, the global epoxy resin market is projected to reach $15.89 billion by 2027, highlighting a growing demand for quality stamping tools that enhance productivity and output quality.

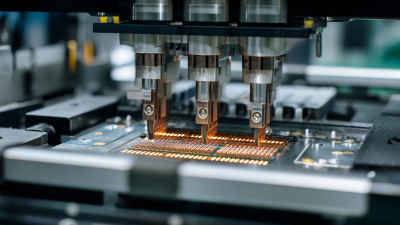

Manual epoxy stamping tools are ideal for small-scale projects and businesses just starting out, offering affordability and straightforward usability. On the other end, pneumatic and electric options are designed for high-volume production environments. For instance, a study from Plunkett Research reveals that companies implementing electric stamping solutions can increase their operational efficiency by up to 25%. Therefore, choosing the right type of epoxy stamping tool not only aligns with your production goals but also ensures that you are keeping pace with industry advancements and client expectations.

When selecting the best epoxy stamping tools for your business, it’s essential to focus on key features that can enhance both efficiency and quality. With the global epoxy coating market projected to grow from $36.53 billion in 2021 to $52.13 billion by 2028, translating to a compound annual growth rate (CAGR) of 5.2%, the demand for reliable and effective tools is on the rise. This growth underscores the importance of investing in high-quality stamping tools that can keep pace with industry advancements.

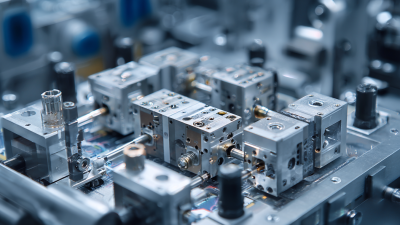

One crucial feature to look for is the tool’s material composition and build quality, as these factors directly influence durability and performance. Tools made from reinforced composites, particularly those utilizing advanced epoxy technologies, tend to withstand the rigors of manufacturing environments better than traditional materials. Additionally, consider features like ergonomic design for ease of use, precision mechanisms for accuracy, and compatibility with various epoxy formulations, which are essential for achieving optimal results in your projects. By prioritizing these key attributes, your business can effectively respond to the increasing market demands.

When it comes to selecting the ideal epoxy stamping tool for your business, comparing popular brands is crucial. Each brand often highlights its unique features, and understanding these can significantly impact your choice. Brands like Xtreme and StampPro have carved out their niches in the market, providing tools that cater to both hobbyists and professional users. Xtreme boasts a powerful motor and an ergonomic design, ensuring prolonged use without discomfort, while StampPro offers precision controls for intricate stamping tasks.

Another noteworthy competitor is EpoxyMaster, which has gained a reputation for its durable materials and ease of use. This brand particularly appeals to newcomers in the epoxy world, thanks to its straightforward assembly process and comprehensive instructional materials. In contrast, thermoplastic-based tools from companies like ProSeal have emerged as favorites for those focusing on industrial applications, thanks to their high resistance to heat and chemicals. By closely examining these brands and their respective strengths, business owners can make an informed decision, ensuring that they choose an epoxy stamping tool that aligns perfectly with their operational needs.

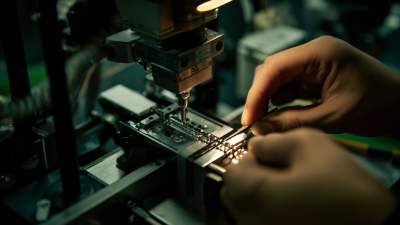

Maintaining your epoxy stamping tools is essential for ensuring their longevity and optimal performance. Regular cleaning should be a top priority; after each use, make sure to wipe down your tools with an appropriate solvent to remove any resin residues. Neglecting this step can lead to build-up that may affect the quality of your stamps in future projects. Additionally, inspect your tools for any signs of wear or damage. Addressing small issues before they escalate can save you from costly replacements down the line.

Proper storage of your epoxy stamping tools is equally important. Store them in a dry, temperature-controlled environment to prevent exposure to moisture, which can lead to rust or degradation of materials. Utilizing protective cases or foam inserts can minimize the risk of physical damage during handling or transport. Furthermore, if your tools have interchangeable parts, keep these parts organized and secure to avoid misplacement. By implementing these maintenance tips, you can extend the life of your epoxy stamping tools, ensuring they remain reliable assets for your business.

| Tool Type | Material | Weight | Price | Recommended Maintenance Frequency |

|---|---|---|---|---|

| Epoxy Roller | Polyester | 0.5 kg | $15 | Every 3 months |

| Epoxy Stamping Machine | Aluminum | 15 kg | $1200 | Every 6 months |

| Epoxy Brush | Nylon | 0.2 kg | $8 | After each use |

| Epoxy Squeegee | Rubber | 0.3 kg | $10 | Monthly |

| Epoxy Stamper | Steel | 1 kg | $40 | Every 3 months |

When it comes to investing in epoxy stamping tools for your business, the balance between cost and quality is crucial. According to a recent industry report by the National Association of Manufacturers, businesses that prioritize quality over price tend to see a 30% increase in operational efficiency. This is particularly relevant in the epoxy stamping sector, where precision and durability are paramount. Investing in high-quality tools may involve a higher initial outlay, but it often leads to longer tool life and reduced replacement costs over time.

Tip: Always assess the warranties offered by manufacturers. A robust warranty can be an indicator of the tool’s quality and provide peace of mind for your investment.

Moreover, various studies indicate that using subpar tools can lead to production flaws that are costly in the long run. Research from the Institute of Industrial Technology shows that companies can expect a 15% rise in scrap rates when using lower-quality tooling. Therefore, while it may be tempting to select a cheaper option, consider the long-term implications on both your product quality and your bottom line.

Tip: Look for tools that incorporate advanced materials or engineering techniques, as these often yield better performance and longevity, justifying the higher initial cost.