When embarking on electronics projects, selecting the right equipment is crucial for achieving optimal results and ensuring reliable performance. One such essential tool in the assembly process is the Tpt Wire Bonder. This specialized device facilitates the precise bonding of wires to electronic components, significantly impacting the durability and functionality of the finished product. However, with a plethora of options available in the market, choosing the appropriate Tpt Wire Bonder can be daunting for hobbyists and professionals alike.

Understanding the various features, specifications, and capabilities of Tpt Wire Bonders is key to making an informed decision. Factors such as the type of materials being bonded, the scale of the project, and the desired bonding techniques must be evaluated to identify the most suitable option. This guide aims to provide insights into the essential considerations when selecting a Tpt Wire Bonder, helping individuals optimize their electronics projects while avoiding common pitfalls associated with improper tool choices. By the end of this discussion, readers will be equipped with the knowledge necessary to confidently choose the right Tpt Wire Bonder tailored to their specific needs.

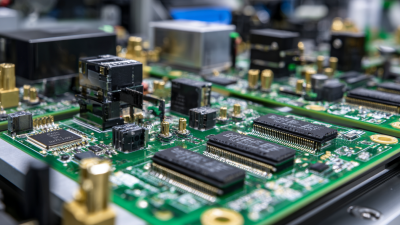

Tpt wire bonding technology plays a crucial role in the electronics manufacturing industry, specifically in device interconnects. At its core, wire bonding is a method used to connect small pieces of metal wire, typically gold or aluminum, between the microchip and its packaging. This technique is essential for ensuring reliable electrical connections and is widely employed in the production of integrated circuits and semiconductor devices. Understanding the basic principles of wire bonding, including thermocompression and ultrasonic bonding processes, is key for anyone looking to effectively utilize this technology in their projects.

One of the fundamental concepts in wire bonding is the choice of wire material and diameter, which can significantly impact the performance and reliability of the connections. Factors such as thermal conductivity, tensile strength, and the bonding environment will influence the selection of the appropriate wire. Additionally, the design of the bonding pad and the arrangement of the wires must be carefully considered to optimize the performance of the assembly. By grasping these fundamental aspects of Tpt wire bonding technology, electronics enthusiasts and engineers can make informed decisions in the development and enhancement of their electronic devices.

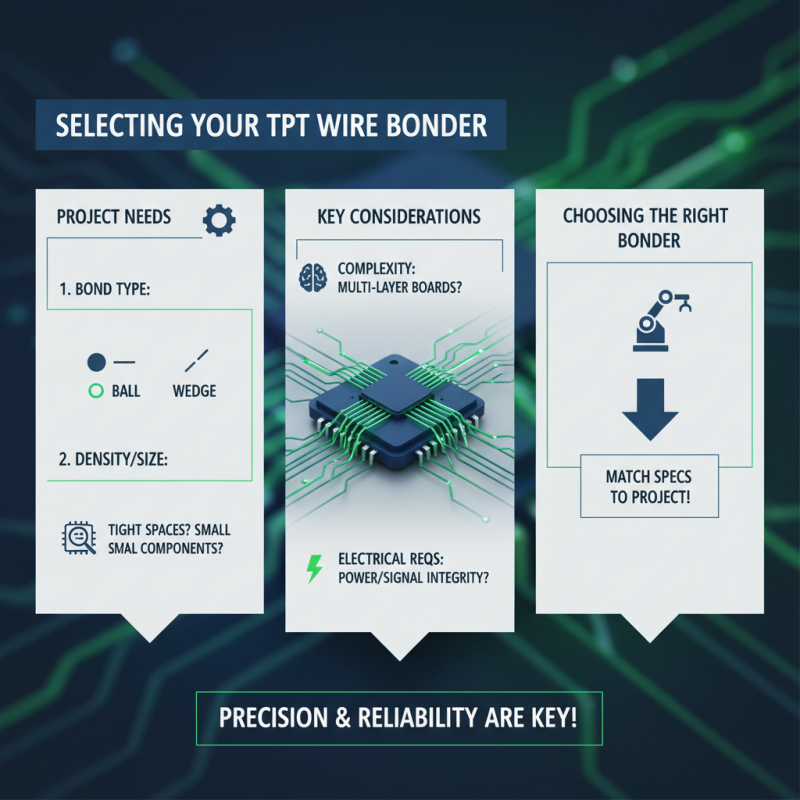

When selecting the right TPT wire bonder for your electronics projects, it is crucial to first identify your specific project needs. Different projects can require various types of bonding processes, so understanding whether you need ball bonding or wedge bonding can significantly impact your choice. For instance, if your project involves densely packed microelectronics, you may benefit from a bonder adept at working in tight spaces and capable of making precise connections. Assessing the size, complexity, and electrical requirements of your project will help you pinpoint the necessary specifications for your wire bonder.

Additionally, consider the materials involved in your project. Different wire materials, such as gold, aluminum, or copper, may require distinct bonding techniques and parameters. Understanding the compatibility of your chosen materials with the bonding method will ensure a robust and reliable connection. Furthermore, budget constraints and expected production volume are practical aspects that could influence your selection. By carefully analyzing these factors, you can make an informed decision on the wire bonder that will best meet your project needs, ultimately leading to a successful electronic assembly.

When selecting a Tpt wire bonder for electronics projects, understanding the key features that enhance performance and reliability is crucial. One of the primary considerations should be the bonding method; ultrasonic, thermosonic, and hot bond techniques each offer distinct advantages depending on the materials and assembly requirements. According to a recent market analysis, ultrasonic bonding accounts for approximately 40% of the global wire bonding market due to its efficiency in high-output environments. Evaluating the bonding force adjustment capabilities is equally essential, as precision in this area can dramatically affect the strength and quality of the bonds.

Another significant feature to consider is the wire diameter compatibility. Depending on the specific components being assembled, the ability to work with varying wire gauges—typically ranging from 25 to 50 microns—is vital. Reports indicate that there is a growing demand for finer wire diameters, driven by the miniaturization of electronic devices. Furthermore, the efficiency of the bonding process can be augmented by features such as programmable settings and automated height adjustments, which reduce setup time and enhance productivity. A well-equipped Tpt wire bonder not only streamlines operations but also improves yield rates, making it an indispensable tool in the electronics fabrication process.

When selecting a TPT wire bonder for electronics projects, it’s essential to evaluate the various models and brands available in the market. Each model offers unique features that cater to different applications, such as thermocompression bonding, ultrasonic bonding, and thermosonic bonding. According to a recent market analysis by Industry Research, the wire bonding equipment market is expected to grow at a CAGR of 5% from 2021 to 2026, driven by demand in the semiconductor industry. This growth highlights the importance of choosing a bonder that aligns not only with current technological demands but also anticipates future advancements.

In evaluating different TPT wire bonder models, factors such as bonding speed, accuracy, and ease of use should be prioritized. For instance, a study from the International Journal of Microelectronics and Solid State Devices revealed that models with advanced automation capabilities significantly reduce cycle times, which enhances productivity in high-volume manufacturing environments. Furthermore, user-friendly interfaces and robust customer support are critical considerations that can affect your workflow efficiency. Ultimately, a well-informed decision in selecting a TPT wire bonder can greatly impact the success of your electronics projects while ensuring you stay competitive within the rapidly evolving tech landscape.

When considering the purchase of a TPT wire bonder, budget considerations play a crucial role in making an informed decision. Establishing a clear budget will help narrow down the viable options based on your specific project needs. Factors to consider include not only the initial purchase price of the wire bonder but also the ongoing costs related to maintenance, consumables, and potential training for operators. A well-planned budget can help you allocate resources effectively and avoid overspending on features that may not be necessary for your project.

In addition to the initial costs, it's essential to assess the long-term value of the wire bonder you are considering. Investing in a slightly more expensive model may yield better performance and reliability, saving money in the long run through reduced downtime and fewer repairs. Furthermore, evaluate the cost-benefit ratio of different functionalities, such as automation features or service support, which could impact the overall effectiveness of your electronics projects. Balancing upfront costs with long-term benefits ensures you choose a TPT wire bonder that aligns with both your budget and project requirements.

| Model | Price Range | Features | Ideal For | Warranty |

|---|---|---|---|---|

| Model A | $2,000 - $3,000 | High precision, automatic wire feeding, programmable settings | Professional use, small to medium-sized projects | 2 years |

| Model B | $1,000 - $1,800 | Manual control, standard features, moderate speed | Hobbyists, educational use | 1 year |

| Model C | $3,500 - $5,000 | Advanced automation, customizable settings, high throughput | High volume production, industrial applications | 3 years |

| Model D | $800 - $1,200 | Basic functionalities, lightweight design | Small projects, DIY enthusiasts | 6 months |