When it comes to selecting the right equipment for your manufacturing processes, choosing the appropriate Hesse Bonder is crucial for ensuring quality and efficiency. Hesse Bonders are renowned for their precision and reliability in adhesive bonding, making them a popular choice among manufacturers across various industries. However, with numerous models and specifications available, it can be daunting to determine which Hesse Bonder best meets your specific needs. In this blog, we will explore essential considerations such as the types of materials you'll be working with, production volume, and technological features, helping you to make an informed decision. Whether you are upgrading your existing systems or starting a new project, understanding these key factors will guide you in selecting the ideal Hesse Bonder that enhances your manufacturing capabilities and contributes to your overall success.

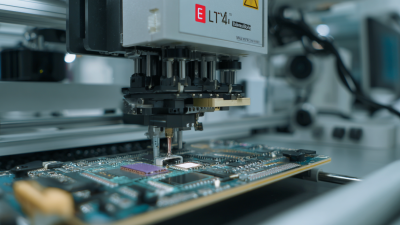

When selecting the right Hesse bonder for your manufacturing needs, it's essential to understand the various types available and their specific applications.

Hesse bonders are known for their versatility in the bonding process, which may vary from wire bonding to die bonding. Each type of bonder is engineered to cater to different requirements, whether you are working with delicate semiconductor components or large-scale assembly in automotive manufacturing.

Knowing the nuances of each bonder type will empower you to make an informed decision that aligns with your production goals.

Hesse bonders are known for their versatility in the bonding process, which may vary from wire bonding to die bonding. Each type of bonder is engineered to cater to different requirements, whether you are working with delicate semiconductor components or large-scale assembly in automotive manufacturing.

Knowing the nuances of each bonder type will empower you to make an informed decision that aligns with your production goals.

Recent market trends indicate significant growth in the TCB bonding sector, with a projected market size of $10.1 billion in 2024, which is anticipated to expand to $36.4 billion by 2033. The compound annual growth rate (CAGR) of 15.1% during this forecast period highlights the increasing demand for advanced bonding technologies. Understanding these market dynamics is crucial for manufacturers looking to invest in efficient and cost-effective bonding solutions. Opting for the right Hesse bonder can not only streamline your production processes but also elevate the quality and reliability of your end products.

When selecting the right Hesse bonder for your production line, it's critical to consider various key factors that can significantly impact your manufacturing efficiency and output. Firstly, assess the specific bonding requirements of your application. Different Hesse bonders offer unique capabilities regarding adhesive types, curing times, and compatibility with materials, which can influence the quality and reliability of the bonded products.

Additionally, the efficiency of your production line can be enhanced by analyzing the automation features of the Hesse bonder. With the global automotive robotics market expected to reach a value of $9.92 billion in 2024, and growing further to $26.76 billion by 2032, automation in manufacturing has never been more crucial. Choosing a bonder that integrates seamlessly with your existing automated systems can streamline operations, reduce manual labor, and ultimately lead to increased productivity.

Furthermore, consider the after-sales support and availability of spare parts for maintenance. A robust support system ensures minimal downtime, keeping your production line running smoothly. As manufacturers increasingly invest in advanced bonding technologies, having a reliable partner for technical assistance can make a significant difference in maintaining consistent production quality.

When selecting the right Hesse bonder for your manufacturing needs, evaluating performance and reliability is crucial. Recent advancements, particularly in the assessment of bonding performance in metal/polymer-based composites, underscore the importance of specifications. Reports indicate that the reliability of bond interfaces can significantly impact overall structural integrity; for instance, geometric uncertainties can lead to variations in bonding outcomes, affecting product longevity and safety. Understanding how different bonding parameters interact can guide you in selecting a bonder that meets your specific application demands.

Tip: Focus on the interface bonding strength specified for your materials. The ideal Hesse bonder should demonstrate robust performance in various environmental conditions, especially if your application involves exposure to temperature fluctuations or chemical agents.

Additionally, consider the technological advancements in bonding methodologies. For instance, the latest predictive methods involving multi-fidelity regression and artificial neural networks provide deeper insights into bonding mechanisms. This knowledge can help you make informed decisions, optimizing your bonding process to ensure consistency and reliability.

Tip: Evaluate the bonder's versatility in handling different substrates, as the ability to work with varying materials is essential for enhancing operational flexibility in manufacturing environments.

When selecting a Hesse bonder for your manufacturing needs, the balance between cost and quality is crucial. Industry reports indicate that investing in higher-quality bonding machines can lead to a significant reduction in defects—up to 30% according to a 2022 study by Manufacturing Insights. This reduction not only enhances product longevity but also minimizes costly rework and scrap rates, which can average around 15% in lower-quality setups. Therefore, while the initial price of quality machines might be higher, the long-term savings make them a wise investment.

Moreover, understanding the total cost of ownership (TCO) is essential. Research by the Equipment Reliability Institute suggests that businesses may spend nearly 25% more over five years on maintenance and repairs for lower-cost machines compared to their premium counterparts. This includes factors like downtime, lost labor productivity, and material waste. By prioritizing quality in your Hesse bonding machine selection, you're not just buying equipment—you're investing in operational efficiency and product excellence. Choosing wisely can lead to sustainable growth and a stronger competitive edge in the market.

When it comes to maintaining your Hesse Bonder for optimal longevity, understanding key maintenance practices is crucial. Regular inspections are essential to identify any wear and tear that may affect performance. Just as bond-building treatments can revitalize damaged hair, routine maintenance can enhance the longevity and efficiency of your Hesse Bonder. Keep the machine clean and well-lubricated, and ensure that all components are functioning smoothly. A proactive approach prevents unexpected breakdowns and supports continuous manufacturing processes.

Optimizing your Hesse Bonder's performance is not just about routine maintenance; it also involves training personnel on its proper use. Just like the best bond repair treatments for hair, a well-trained team can effectively troubleshoot minor issues before they escalate into larger problems. Incorporate regular training sessions to familiarize operators with the latest features and best practices. This not only boosts confidence but ensures that your equipment remains in top shape, ultimately leading to improved productivity and reduced downtime in your manufacturing operations.