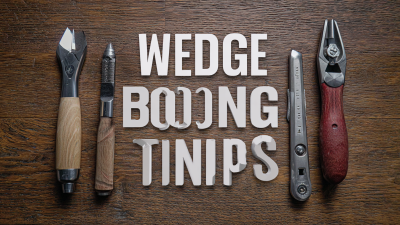

In the rapidly evolving landscape of semiconductor manufacturing, the efficiency of production processes is paramount. Recent industry reports highlight that optimizing production efficiency can increase output by up to 30%, a significant benefit in a market where precision and speed are crucial. Among the various techniques employed to enhance manufacturing efficiency, Wedge Bonding Tools have emerged as a game-changer. These tools, known for their ability to create tightly bonded connections in microelectronic components, are integral to the assembly of advanced packages. According to a study by Industry Research, the adoption of high-quality Wedge Bonding Tools can reduce cycle times and improve yield rates, making them essential for manufacturers aiming to stay competitive in an increasingly demanding market. This blog will explore the 7 best Wedge Bonding Tools of 2023, providing insights into their features and how they can significantly contribute to boosting your production efficiency.

Wedge bonding technology has increasingly gained prominence in modern manufacturing, particularly within the semiconductor sector. This process is vital for joining various materials with high precision, thus enhancing production efficiency. Recent studies have shown that the use of wedge bonding can improve production rates by up to 30%, making it a crucial component for manufacturers aiming to keep pace with rising demands. As the need for advanced integrated circuits grows, the importance of efficient bonding methods cannot be overstated.

Moreover, advancements in adhesive bonding techniques are playing a pivotal role in enhancing the performance of composite materials and structures. A comprehensive review of adhesively bonded joints (ABJs) highlights their significance in achieving robust and reliable connections. The synergy between wedge bonding and ABJs embodies the industry's shift toward more efficient manufacturing practices. By harnessing these technologies, manufacturers can navigate the challenges presented by increased production pressures and quality standards, thereby securing their competitive edge in the marketplace.

When selecting wedge bonding tools, one of the key features to consider is the bonding capability of the tool. High-quality wedge bonders should be capable of handling various materials, such as gold, aluminum, and silver, with precision. Ensure that the tool you choose can operate effectively under different environmental conditions, as this flexibility can significantly enhance production efficiency.

Another important aspect is the ease of use and maintenance of the equipment. Opt for models that offer intuitive controls and automation features, which can reduce the learning curve for operators and minimize downtime. Regular maintenance should also be straightforward to keep the tool in optimal condition, ultimately contributing to increased productivity.

Lastly, consider the compatibility of the tool with existing manufacturing systems. It is essential that the wedge bonding equipment can integrate seamlessly with your current setup to prevent any disruptions in workflow. Investing in tools that offer advanced connectivity options or software compatibility can enhance overall operational efficiency. Be sure to evaluate customer support and warranty options as well, as these factors can greatly influence your experience and peace of mind when using the equipment.

In the fast-paced landscape of semiconductor manufacturing, wedge bonding tools have become integral for improving production efficiency. According to a report by the Semiconductor Industry Association (SIA), the global semiconductor revenue is projected to reach $500 billion by 2025, highlighting the need for advanced manufacturing technologies. Among the myriad equipment available, the top wedge bonding tools in 2023 stand out for their precision, reliability, and capability to streamline processes. Recent studies indicate that the implementation of these advanced tools can enhance production efficiency by an impressive 30%, making them essential for manufacturers aiming to stay competitive.

Leading the market are tools that incorporate innovations such as ultrasonic welding and real-time monitoring systems. For example, a comparative analysis from TechInsights reveals that manufacturers utilizing modern wedge bonding systems have reported a 20% reduction in operational costs, primarily due to minimized material wastage and increased throughput. Furthermore, advancements in automation allow for seamless integrations with existing processes, enabling operators to achieve consistent quality and improved cycle times. As these tools become more sophisticated, they not only increase productivity but also refine the accuracy of wire placement, which is critical for high-performance semiconductor devices.

Upgrading your wedge bonding tools can significantly boost production efficiency, making it a crucial investment for any manufacturing facility. The latest advancements in wedge bonding technology not only enhance the reliability of connections but also contribute to a smoother workflow. With improved precision and reduced cycle times, businesses can achieve higher output rates. This is particularly beneficial in industries such as semiconductor manufacturing and electronics, where the demand for high-quality, durable bonds is ever-increasing.

Moreover, modern wedge bonding tools come equipped with advanced features such as automated parameters and real-time monitoring, allowing operators to adjust processes on-the-fly. By integrating these tools into your production line, you can minimize downtime and reduce the chances of human error. The ability to achieve consistent quality leads to fewer reworks and wasted materials, optimizing overall resource utilization.

The benefit of upgrading extends beyond immediate operational gains, fostering a culture of innovation that can ultimately set your company apart in a competitive market.

When it comes to enhancing production efficiency, optimizing the use of wedge bonding tools can significantly increase output. The effective deployment of these tools not only streamlines the bonding process but also helps in maximizing the overall capacity utilization rate. By understanding the ideal settings and conditions for each wedge bonding operation, manufacturers can achieve higher levels of production efficiency, targeting an improvement of up to 30%.

To maximize production output with wedge bonding tools, it is crucial to adhere to best practices. First, ensure that the tools are properly calibrated to the specific materials being used, as incorrect settings can lead to waste and downtime. Additionally, regular maintenance of both the tools and equipment is essential to prevent any disruption in the bonding process. Training staff on the optimal techniques and the importance of monitoring capacity utilization can further highlight production inefficiencies, allowing for timely adjustments that contribute to sustained output improvements. By focusing on these key aspects, businesses can fully leverage the capabilities of wedge bonding tools to enhance their production efficacy.