In the fast-evolving landscape of manufacturing, efficiency and precision are paramount. The Westbond Wire Bonder has emerged as a crucial tool for manufacturers aiming to enhance their production processes. Known for its reliability and advanced technology, this wire bonder offers a multitude of benefits that can significantly impact the overall quality and efficiency of manufacturing operations. From improving bond strength to increasing throughput, the advantages of utilizing a Westbond Wire Bonder are numerous and compelling.

Manufacturers are constantly seeking solutions that not only meet their immediate needs but also prepare them for future challenges. The Westbond Wire Bonder stands out by providing consistent performance and adaptability to various production environments. With its user-friendly interface and automated features, it simplifies complex bonding tasks, allowing operators to focus on other critical aspects of manufacturing. In this article, we will explore the top 10 benefits of using the Westbond Wire Bonder, highlighting how it can transform manufacturing capabilities and contribute to a more streamlined and effective production process.

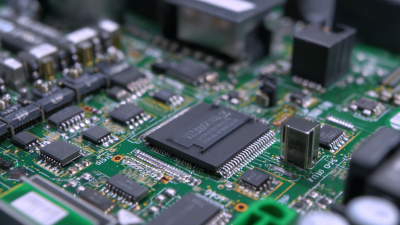

In high-volume manufacturing environments, the efficiency and reliability of operations are crucial. One of the significant advantages of utilizing a state-of-the-art wire bonder is its ability to streamline production processes. These machines are designed for speed and precision, allowing manufacturers to maintain high throughput without sacrificing quality. The automation capabilities in modern wire bonders reduce the potential for human error, leading to consistent results across vast quantities of products.

When choosing a wire bonder for high-volume production, here are a few tips to consider:

Additionally, investing in a wire bonder with robust programming capabilities can significantly enhance the customization of bonding processes. This adaptability can be essential in meeting the specific requirements of diverse projects while still achieving rapid turnaround times. Ultimately, leveraging these features can lead to substantial cost savings and efficiency gains in high-volume manufacturing scenarios.

In the realm of manufacturing, precision and accuracy are paramount, particularly in bonding processes. Utilizing advanced wire bonding technology can significantly enhance the quality of production, ensuring that components are securely and effectively joined. This enhancement in precision reduces the likelihood of defects and improves overall product reliability, ultimately leading to increased customer satisfaction.

The mechanisms behind modern wire bonders contribute to their accuracy. With features such as advanced thermal control, real-time monitoring, and precision motion systems, these machines can execute intricate bonding tasks with remarkable consistency. The ability to control variables such as bonding temperature and force allows manufacturers to tailor processes to meet specific requirements, resulting in stronger and more durable connections. Over time, this attention to detail not only streamlines operations but also minimizes material waste, providing an important advantage in cost management and environmental responsibility.

The following bar chart illustrates the top 10 benefits of using wire bonders in manufacturing processes, highlighting enhanced precision and accuracy in bonding.

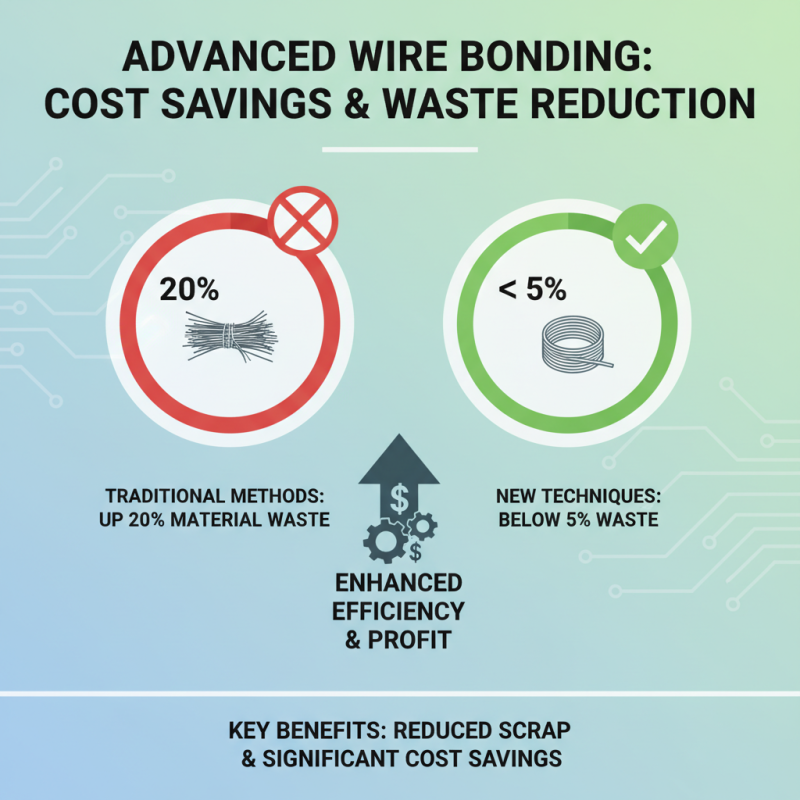

In the competitive landscape of manufacturing, cost-effectiveness and waste reduction are paramount. Implementing advanced wire bonding technologies can play a crucial role in enhancing operational efficiency. Studies have shown that traditional bonding methods can lead to significant material waste—often as high as 20%—due to misalignment and ineffective process controls. By contrast, new wire bonding techniques minimize scrap and ensure more precise application, potentially reducing waste to below 5%, which translates into substantial cost savings over time.

Moreover, the adoption of modern bonding systems has been linked to a decrease in production turnaround times. According to a recent industry report, manufacturers utilizing optimized wire bonders have experienced up to a 30% reduction in production cycles, which not only lowers labor costs but also accelerates time-to-market. This efficiency allows companies to invest savings into further innovation and quality improvements, thereby establishing a competitive edge. By prioritizing technology that bolsters cost efficiency and minimizes waste, manufacturers can ensure sustainable operations while maximizing their return on investment.

The versatility of a wire bonder in manufacturing cannot be overstated, as it caters to a diverse range of materials and applications. In modern electronics assembly, wire bonders are crucial for ensuring reliable connections in devices made from various substrates, including silicon, ceramics, and organic materials. This adaptability enables manufacturers to streamline their processes, reducing downtime associated with switching between machines or techniques. As a result, businesses can efficiently meet production demands while maintaining high standards of quality across different products.

In addition to accommodating multiple materials, wire bonders support various bonding techniques, such as ball bonding and wedge bonding. This flexibility allows manufacturers to optimize their operations according to the specifications of individual projects. The ability to bond different metals, including aluminum and gold, further enhances the utility of these machines in sectors like telecommunications, automotive, and consumer electronics. Manufacturers can thus achieve the desired performance characteristics for their products, securing an edge in competitive markets by offering customized solutions tailored to specific applications and material profiles.

The integration of advanced wire bonding technology into manufacturing processes has demonstrated a significant enhancement in efficiency and productivity. A recent industry analysis indicated that manufacturers utilizing state-of-the-art wire bonders, such as those with automated capabilities, reported up to a 30% reduction in production cycle times. This efficiency translates to increased throughput, allowing companies to meet rising consumer demands without compromising quality.

Moreover, the precision offered by modern wire bonding equipment minimizes material waste and reduces the likelihood of rework. According to data from manufacturing efficiency reports, organizations that adopted automated wire bonding techniques experienced a 25% decrease in material usage, resulting in substantial cost savings over time. This meticulous approach not only bolsters overall productivity but also fosters sustainable manufacturing practices, which are increasingly critical in today's environmentally conscious landscape. By optimizing production workflows and minimizing waste, manufacturers can achieve a competitive edge and adapt more readily to market changes.

| Benefit | Description | Impact on Operations |

|---|---|---|

| Enhanced Speed | Increased speed of wire bonding processes | Reduces production time and increases output |

| Higher Precision | Improved accuracy in bond placement | Minimizes defects and rework |

| Cost Efficiency | Reduces material waste and labor costs | Maximizes profit margins |

| Scalability | Easily adapts to varying production volumes | Supports growth and market demand |

| User-Friendly Interface | Intuitive controls and software integration | Reduces training time and errors |

| Versatility | Compatible with various materials and components | Expands application range |

| Reduced Downtime | Minimized maintenance and repair time | Ensures continuous production |

| Improved Quality Control | Advanced monitoring and feedback systems | Enhances product consistency |

| Better Compliance | Supports industry standards and regulations | Reduces regulatory risks |

| Energy Efficiency | Lower energy consumption during operations | Decreases energy costs |