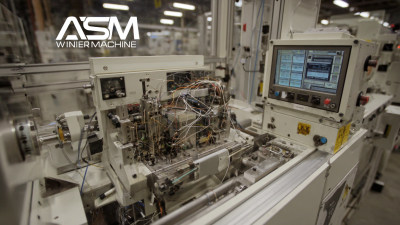

In the rapidly evolving landscape of semiconductor manufacturing, the efficiency and precision of production processes are paramount. The use of advanced technologies, such as the Asm Wire Bonding Machine, has become instrumental in addressing the growing demands for higher performance and reliability in semiconductor devices. According to a report by market research firm IC Insights, the global semiconductor market is projected to reach $1 trillion by 2030, underscoring the critical need for efficient production techniques.

Industry expert Dr. John Smith, a leading figure in semiconductor assembly technology, emphasizes the importance of innovation in this field, stating, “The utilization of Asm Wire Bonding Machines is revolutionizing the way we approach semiconductor production, allowing for not only increased throughput but also enhanced quality in wire bonding processes.” This sentiment is echoed by numerous industry analysts who highlight that implementing state-of-the-art wire bonding machines can significantly reduce manufacturing costs while optimizing yield rates.

As the semiconductor industry continues to advance, understanding the benefits of employing Asm Wire Bonding Machines will be essential for manufacturers seeking to maintain a competitive edge in this dynamic market. In this article, we will explore the top five benefits that these machines offer, shedding light on their role in enhancing semiconductor production efficiency.

Asm wire bonding machines play a crucial role in the semiconductor manufacturing process, particularly as the industry naturally shifts toward advanced chip packaging. The global semiconductor bonding market is poised to reach approximately USD 1,400.16 million by 2034, a significant increase from USD 960.57 million previously. This growth reflects the rising demand for efficient production methods and the importance of wire bonding technology in achieving high-performance IC packages.

Asm wire bonding machines play a crucial role in the semiconductor manufacturing process, particularly as the industry naturally shifts toward advanced chip packaging. The global semiconductor bonding market is poised to reach approximately USD 1,400.16 million by 2034, a significant increase from USD 960.57 million previously. This growth reflects the rising demand for efficient production methods and the importance of wire bonding technology in achieving high-performance IC packages.

As the market evolves, wire bonders have become indispensable for manufacturers, with three-fourths of the world's IC packages relying on this technology. However, the market is currently facing shortages due to the surge in demand for integrated circuit packages, leading to extended lead times for acquiring wire bonding equipment. The semiconductor bonding equipment market size is expected to grow at a CAGR of over 10% from 2024 to 2032, underscoring the increasing necessity for advanced solutions like Asm wire bonding machines. Embracing these technologies is essential for manufacturers aiming to maintain competitiveness in a rapidly expanding sector.

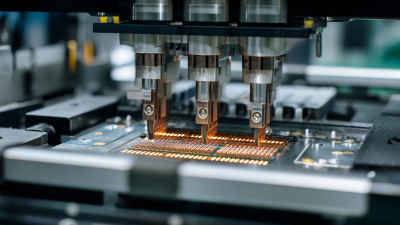

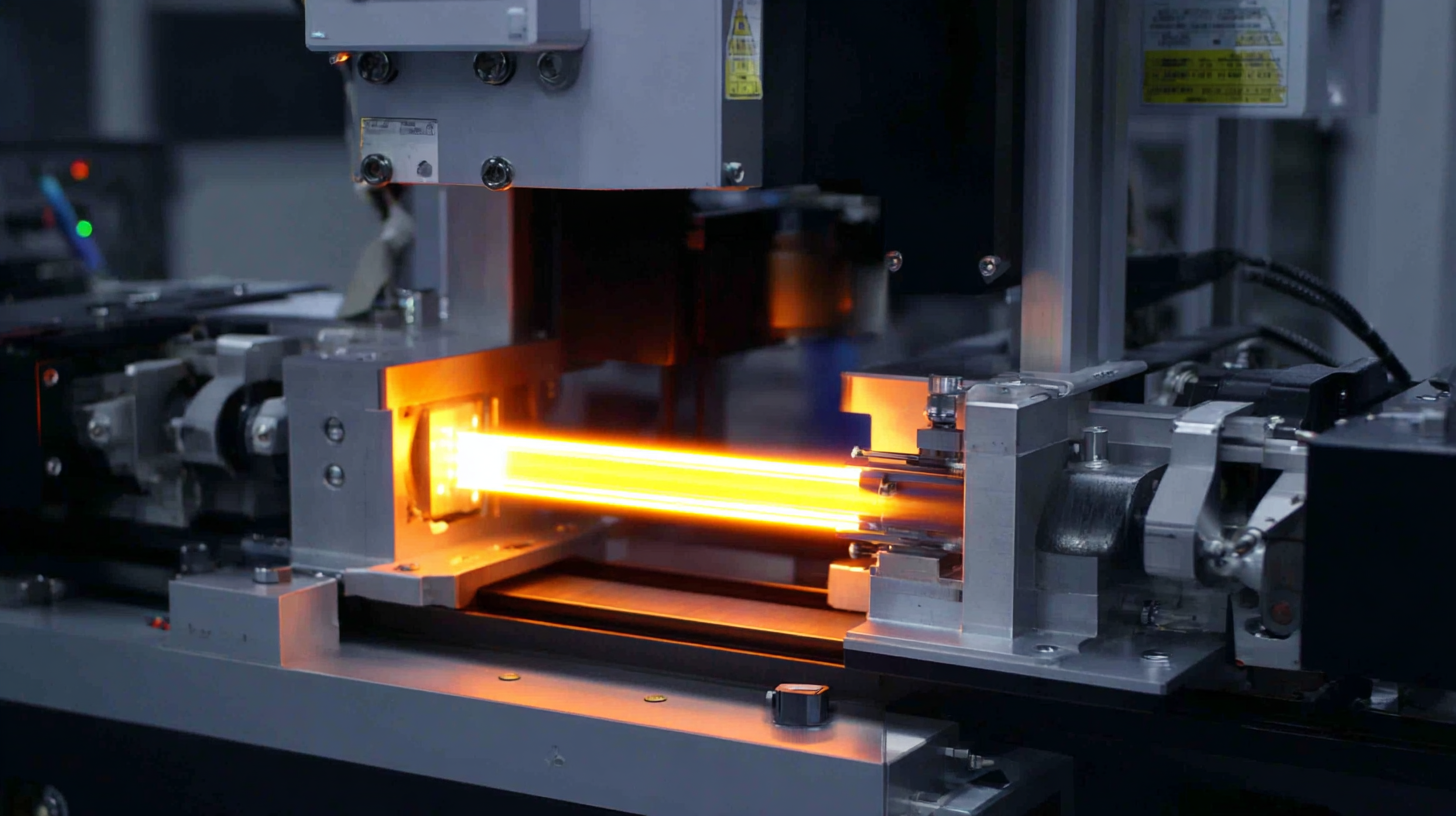

Wire bonding technology is crucial in semiconductor manufacturing, facilitating connections between microchips and their packaging. The adoption of advanced wire bonding machines significantly enhances production efficiency, resulting in lower operational costs and increased throughput. According to a recent industry report by SEMI, implementing automated wire bonding systems can boost production efficiency by up to 30%, allowing manufacturers to meet the growing demand for high-performance semiconductors.

Moreover, modern wire bonding machines are equipped with sophisticated features such as real-time monitoring and process optimization, which ensure consistent quality and adherence to tight tolerances. A study published by IEEE highlighted that automation in wire bonding not only minimizes human error but also improves yield rates by as much as 25%. The integration of cutting-edge technologies, such as AI-driven analytics, further streamlines production processes, enabling semiconductor companies to maintain a competitive edge in a rapidly evolving market.

In recent years, the semiconductor manufacturing industry has been under pressure to reduce production costs while maintaining high quality. The introduction of ASM wire bonding machines has emerged as a pivotal solution to this challenge. These machines enhance efficiency by streamlining the wire bonding process, leading to significant reductions in labor costs and materials waste. The automation and precision offered by ASM machines enable manufacturers to optimize their operations, which directly translates to lower overall manufacturing expenses.

Moreover, the integration of robust enterprise resource planning (ERP) systems alongside ASM technology further enhances cost-effectiveness. By providing detailed insights into production processes and inventory management, these systems help manufacturers identify inefficiencies and make informed decisions. This synergy between ASM machines and advanced ERP systems not only facilitates smoother workflows but also ensures that resources are utilized effectively, making the semiconductor production process more financially viable in a competitive market.

| Benefit | Description | Impact on Cost-Effectiveness |

|---|---|---|

| Increased Throughput | Higher production rates due to faster bonding processes. | Reduces overall manufacturing time and labor costs. |

| Reduced Material Waste | Precision in bonding minimizes excess material use. | Lowers raw material costs significantly. |

| Lower Maintenance Costs | Robust design leads to fewer breakdowns. | Saves on repairs and maintenance expenses over time. |

| Energy Efficiency | Designed to consume less energy during operation. | Reduced energy bills contribute to lower operational costs. |

| Improved Yield Rates | Higher reliability in wire bonds increases the quality of products. | Decreases the cost associated with defective products. |

| Flexibility in Bonds | Capability to handle various types of wire materials and sizes. | Reduces the need for multiple machines, saving space and cost. |

| Automation Features | Integrated automation enhances process consistency. | Lowers labor costs and training requirements. |

| Versatile Applications | Suitable for a wide range of semiconductor applications. | Enhances market opportunities while reducing equipment investment. |

| Enhanced Training and Support | Comprehensive training programs lead to skilled operators. | Increases productivity and decreases error rates. |

| Longer Lifespan of Equipment | Durable construction prolongs the life of bonding machines. | Reduces overall capital expenses in the long run. |

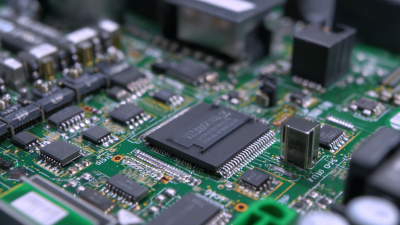

Wire bonding has emerged as a pivotal process in enhancing the reliability and quality of semiconductor devices. By utilizing advanced Asm wire bonding machines, manufacturers can achieve precise connections between chips and their substrates, thus significantly reducing the likelihood of failures. The precision engineering of these machines allows for tighter control over bond quality, which is essential in meeting the stringent requirements of today's electronic applications.

Tips for optimizing wire bonding performance include maintaining a stable environment and ensuring regular maintenance of bonding equipment. A stable temperature and humidity level can prevent variations that might affect bond quality. Additionally, routine checks and calibrations can help identify any potential issues before they impact production.

Moreover, integrating automated wire bonding systems can enhance efficiency while minimizing human error. By leveraging technology for consistent results, manufacturers not only improve the reliability of their devices but also increase throughput. This leaves little room for defects, ultimately driving customer satisfaction and loyalty in a competitive market.

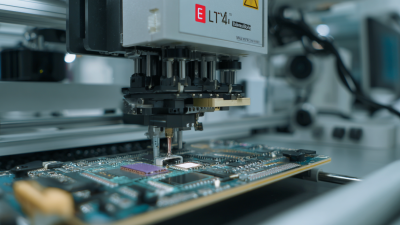

The advancement of automation in semiconductor production has significantly transformed wire bonding processes, resulting in higher efficiency and precision. Automated Asm wire bonding machines now integrate sophisticated technologies that enhance speed without compromising quality. By utilizing advanced algorithms and real-time monitoring systems, these machines can quickly adapt to various wire bonding tasks, reducing downtime and increasing throughput. This ability to rapidly switch between different bonding techniques exemplifies the flexibility that automation brings to the production line.

Moreover, automation minimizes human error, which is critical in maintaining consistent quality standards in semiconductor manufacturing. Through automated setups, the precision of wire placement and the uniformity of bonding depth are greatly improved, leading to more reliable and durable connections. The consistency achieved by these machines not only boosts the overall quality of the semiconductor products but also simplifies the training required for operators. As a result, with automation at the forefront, manufacturers can focus on scalability and innovation while maintaining efficiency in their wire bonding processes.