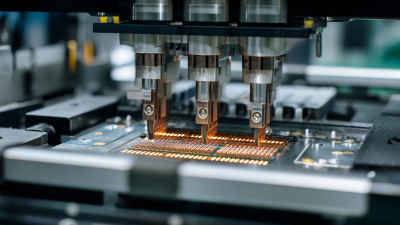

In the realm of semiconductor manufacturing, precision and efficiency are paramount, particularly when it comes to the delicate process of interconnection. Automatic Wire Bonder machines have emerged as essential tools for achieving high-quality wire bonding, significantly enhancing production capabilities. According to Dr. Emily Chen, a leading expert in the field of microelectronics, "The advancements in Automatic Wire Bonder technology have revolutionized the way we approach interconnect solutions, providing unparalleled accuracy and speed."

Today, choosing the right Automatic Wire Bonder can make all the difference in meeting the rigorous demands of the industry. With a variety of models available, each designed with specific functionalities and features, manufacturers are tasked with finding the most suitable option that aligns with their production goals. Whether focusing on reducing cycle times or increasing bond strength, the right machine can enhance operational efficiency and ultimately impact the bottom line.

In this article, we will explore the top seven Automatic Wire Bonder machines that lead the market in both precision and efficiency. By highlighting the best models available, we aim to provide insights that will assist companies in making informed decisions regarding their investment in wire bonding technology.

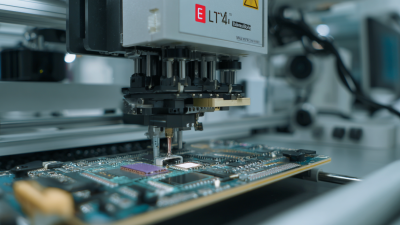

The automatic wire bonder machines are set to play a pivotal role in the evolving landscape of semiconductor packaging and assembly, particularly as we approach 2025. With the increasing focus on smart manufacturing and the need for high-precision solutions, advancements in bonding technology are expected to significantly enhance efficiency and reliability in production environments. Innovations such as AI integration and high-performance computing chips are expected to drive demand for more sophisticated wire bonding methods, pushing manufacturers to adopt cutting-edge solutions.

In light of recent developments showcased at the 40000㎡ flagship exhibition for connector cables and processing equipment, it is clear that the industry is on the cusp of a transformative shift. The integration of automation and artificial intelligence into manufacturing processes will not only optimize performance but also cater to the rising demand for advanced packaging technologies. As companies prepare to meet the expectations for increased productivity and precision, the trends in automatic wire bonder technology will shape the future of semiconductor manufacturing substantially. The convergence of these technologies creates a robust environment for innovations that prioritize efficiency and precision in wire bonding applications.

In the evolving landscape of semiconductor manufacturing, precision and efficiency have become paramount, making high-quality wire bonder machines indispensable. According to a report by MarketsandMarkets, the global wire bonding equipment market is projected to reach USD 1.9 billion by 2025, highlighting the growing demand for advanced machinery that delivers exceptional performance. High-precision wire bonders today offer cutting-edge features such as enhanced control systems, automated alignment processes, and real-time monitoring. These capabilities ensure consistency in bond quality, crucial for meeting the stringent standards of modern electronic applications.

Key features of high-precision wire bonders include advanced ultrasonic bonding capabilities, which facilitate better material compatibility and reduced cycle times. Furthermore, the latest machines come equipped with sophisticated vision systems that allow for precise positioning and adjustments, significantly minimizing human error. A study from TechInsights indicates that machines with automated feedback loops can achieve bond strength improvements of up to 30%, ultimately leading to increased yield and reduced waste. As manufacturers strive for higher efficiency and product reliability, investing in the latest wire bonding technology is not just an option but a necessity for staying competitive in the market.

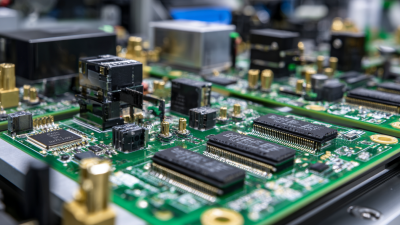

The comparative analysis of efficiency ratings in leading wire bonder models highlights the critical role of precision and performance in the semiconductor manufacturing industry. With the increasing demand for miniature and highly efficient electronic components, the effectiveness of wire bonders has become paramount. The various models available on the market offer different efficiency metrics, impacting production workflows and overall cost-effectiveness.

In similar fashion to the analysis of performance and energy efficiency in high-performance AI applications, assessing wire bonder machines requires a nuanced understanding of their operational parameters. Factors such as cycle time, bond strength, and energy consumption are essential in determining the most suitable equipment for specific applications. By carefully evaluating these efficiency ratings, manufacturers can make informed decisions that align with their production goals while ensuring reliability and quality in their output.

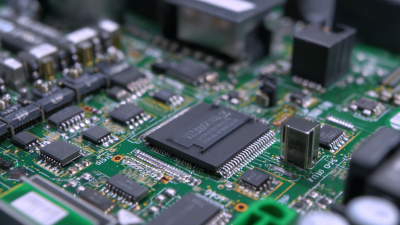

The impact of advanced materials on wire bonder performance and longevity is becoming increasingly significant as the semiconductor industry evolves. According to a report by SEMI, the use of advanced materials such as gold, copper, and silver in wire bonding processes has resulted in improved electrical conductivity and thermal management, which are critical for enhancing the performance of bonded connections. In recent studies, devices utilizing fine-pitch wire bonding and advanced bonding techniques have shown a reduction in interconnect resistance by up to 30%, thereby increasing the overall efficiency of integrated circuits (ICs).

Furthermore, the longevity of wire bonders is heavily influenced by the materials employed in the bonding processes. A recent market analysis by TechInsights indicates that machines utilizing ceramics and high-strength polymers for their components have demonstrated a 25% increase in operational lifespan compared to traditional materials. This improvement not only reduces the frequency of machine downtime but also mitigates maintenance costs, leading to a more sustainable production environment. As manufacturers continue to incorporate these high-performance materials into their wire bonding systems, they can expect noteworthy enhancements in both yield and cost-effectiveness, positioning themselves for long-term success in a competitive market.

As we approach 2025, the wire bonding industry faces a myriad of challenges and opportunities that will shape its future landscape. One of the significant hurdles is the increasing demand for higher performance and miniaturization in electronic components. Manufacturers are under pressure to create wire bonders that operate with greater precision while maintaining efficiency. Innovations in materials and bonding techniques will be essential to meet the needs of advanced technologies, from smartphones to electric vehicles.

At the same time, these challenges present substantial opportunities for growth and development within the industry. Emerging markets, particularly in sectors like automotive and renewable energy, are driving investment into advanced bonding solutions. Additionally, the integration of smart technology and automation in wire bonding processes could streamline operations, reduce costs, and enhance product reliability. Companies that embrace these innovations and adapt to the evolving market demands will not only survive but thrive in the competitive wire bonding environment of the future.

| Model | Bonding Method | Max Bonding Speed (Wires/sec) | Precision (µm) | Automation Level | Applications |

|---|---|---|---|---|---|

| Model A | Ultrasonic | 10 | 5 | Fully Automated | Microelectronics |

| Model B | Wedge | 8 | 7 | Semi-Automated | Consumer Electronics |

| Model C | Ball | 12 | 4 | Fully Automated | Automotive |

| Model D | Laser | 15 | 3 | Fully Automated | Telecommunications |

| Model E | Thermocompression | 9 | 6 | Semi-Automated | Industrial Sensors |

| Model F | Gold Wire | 11 | 5 | Fully Automated | Aerospace |

| Model G | Aluminum Wire | 7 | 8 | Semi-Automated | Computing |